Home » Supply Chain Technology » Intelligent Automated Sourcing

The maintenance, repair, and operations for manufacturing and facilities has always focused on efficiency. The theory was that FM and MRO is a cost of doing business, a necessary expense that should be kept as low as possible. That is still a primary objective today. Producers want to streamline the FM parts and MRO supply chain through automation of repetitive processes so they can invest the preserved resources into more value-added processes and capabilities.

Automated ordering, invoicing, payments, and forecasting continue to squeeze as much value from the FM parts and MRO supply chain as possible, but what if it were possible to not only identify existing sources of value and efficiency but to actually create value from this traditionally neglected supply chain? That’s the promise of FM and MRO sourcing efficiency.

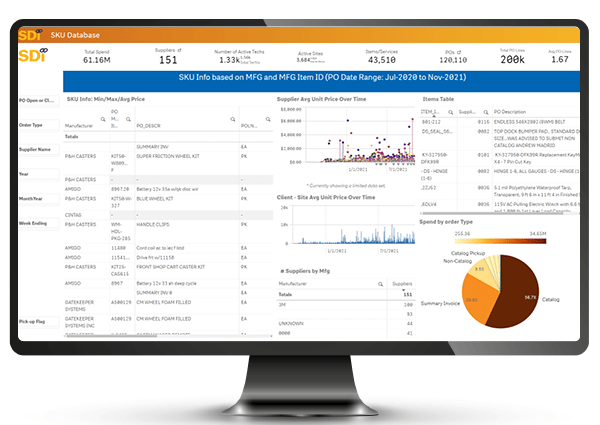

Sourcing MRO materials, FM parts, essential store GNFR, PPE, and other tail spend efficiently hinges on competition among suppliers. SDI’s ZEUS Supply Chain Management platform includes an intelligent sourcing platform to integrate, automate, and digitize the way our customers find, evaluate, work with, and transact with their suppliers.

SDI approaches supplier relationships with the same vigor companies use in hiring employees:

Compelling vendors to compete for your business not only ensures you pay fair market rates, but it also spurs suppliers to offer more inclusive services, advantageous terms, and strategic, innovative solutions.

SDI’s implementation and vendor management procedures ensure our customers establish a method for creating supply chain value, establishing procurement rules, reducing risk, and generally keeping suppliers on their toes.

Sourcing efficiency creates value by building enterprise SKU knowledge base, documenting best vendor-management practices, aggregating orders and suppliers, and pulling the correct “sourcing levers” to the appropriate classes of consumables and spare parts.

There are scores of possible levers, each with unique sets of advantages and drawbacks that make them suitable for different commodities.

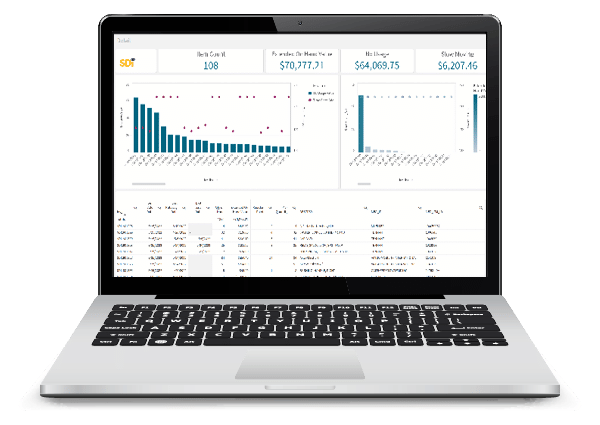

SDI’s automated solution augments our procurement and source-to-pay services to help our customers reduce manual processes and interventions, cutting costs while complying to purchasing rules.

Automated business responses ensure all tasks are accomplished at the right time and that nothing slips through the cracks. Automation is perfect for FM parts and MRO supply reordering, production forecasting, maintenance scheduling, and more.

Machines are the ultimate multitaskers. Computers can compare multiple offers, format data for use in various downstream applications, and generate reports quickly so decisions can be made in real-time.

Automated invoicing, proposal requests communications, scheduling, and other functions handled automatically create a chain of evidence that allows companies to visualize each process. Procurement and facilities/plant management teams can see at-a-glance which vendors responded to an RFP, which were responsive, and which were selected.

SDI automates your procurement and vendor-management processes and ensures their efficacy in cutting supply chain costs and eliminating supply risk.

Read more about why procurement automation should be a priority. Contact SDI for a demonstration of how our strategic sourcing and supply chain automation services can extract sustainable value for your organization.

Copyright ©2025 SDI, Inc.