Home » Supply Chain Services » Supplier Management

SDI, at its core, is a supply chain management company that is focused on creating client value through the efficient and effective management of the parts supply chain – whether your parts are MRO, FM Spares, Goods Not for Resale, Critical Stock, Tail Spend, or other indirect spend. These complex supply chains impact operations and the bottom line. The good news is that they can be optimized through strategic supplier relationship management.

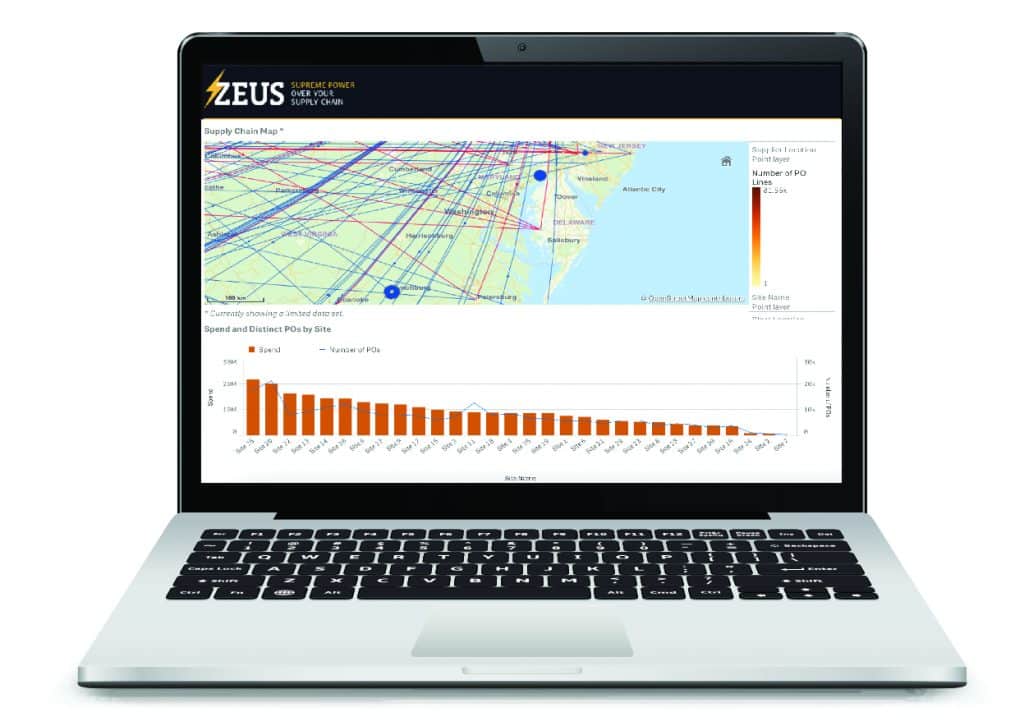

SDI’s Supplier Relationship Management (SRM) team provides holistic, ecosystem-wide visibility of your supply base’s capabilities and the assets that impact your specific business strategy. We develop mutually beneficial relationships with strategic supply partners to deliver greater levels of innovation and competition, managing the entire relationship life cycle, including vetting and onboarding to maximize your program’s value. The SDI team handles all supplier negotiations, sourcing, and performance management to ensure that all MRO and indirect spending contributes to your overall savings.

After a comprehensive data review, we provide strategic sourcing recommendations and source to pay solutions for a truly integrated supply chain. This includes the right sourcing, supplier segmentation, re-sourcing, product standardization, and more.

SDI champions a supplier-agnostic approach, staying brand and supplier neutral in our sourcing & purchasing endeavors. Unlike distributors who prioritize selling specific product lines irrespective of genuine client needs, SDI’s commitment is to deliver optimal value. This approach is evident across diverse sectors, from specialized manufacturing to unique educational institution requirements.

Our extensive supplier network, comprising thousands of relationships, offers clients prompt access to the parts and supplies they need to maintain their facilities and assets. This diverse supply network eliminates the necessity for clients to juggle multiple supplier relationships, allowing them to focus on core operations. Embracing the core tenets of SRM, SDI prioritizes collaborative partnerships, aiming for elevated quality, enhanced supplier performance, and optimized delivery, ordering, and business practices. Our extensive supplier network guarantees that clients attain superior value, bolstered by over five decades of market expertise in competitive bidding.

While cost-efficiency remains pivotal, timely availability is paramount. Thus, beyond pricing, supplier performance in adhering to delivery schedules and other client goals are vital factors in our supplier selection process.

Establishing contract compliance is one part of delivering value. But value really comes from innovative, collaborative activities solving customer problems. SDI ties supplier performance objectives directly to your goals, working together to achieve shared objectives. In MRO and FM, this can lead to supply availability, inventory optimization, cost reductions, and more.

Within our SRM strategy, we regularly meet with suppliers to discuss all aspects of performance. Supplier performance objectives and measurements focus on, and impact, the overall objectives of your business. Understanding the performance of your MRO and FM parts ecosystem is crucial to planning maintenance schedules and allocating labor resources for work order completion. Supplier Scorecards that focus on metrics like on-time delivery, lead time accuracy, and price compliance provide real insight, create transparency to respond, help anticipate, and identify more opportunities for improvement.

SDI’s SRM program manages the high volume of suppliers and interactions efficiently to form an ecosystem delivering maximum value. Contact SDI to leverage our 50+ years of supply chain expertise to drive value from your MRO and FM supplier relationships.

Copyright ©2025 SDI, Inc.