Home » Supply Chain Services » Reliability & Continuous Improvement

We understand that manufacturing and other asset-intensive environments can become entrenched in the day-to-day and struggle to make the shift from reactive to proactive. Making this shift is not easy. You need to step back from the day-to-day to do this. That’s why we’re here.

SDI offers a number of reliability engineering solutions as services or as discrete projects.

SDI’s team of experts will identify the frustrating pain points in your maintenance and repair history. We will then implement systems to eliminate unplanned failures, minimize expensive repairs, and design a just-in-time job kit that ensures your team has the right parts where they need them, when they need them. Beyond simple cost improvement, our reliability engineers pinpoint opportunities associated with issues like chronic equipment failures, emergency work and facility management. We then provide tailored solutions to increase productivity and deliver annualized savings.

Our cradle-to-grave information tracking system gives you an ongoing view of activity, so you can eliminate spending on parts that have failed during or after their warranty period. SDI leverages in-house technical resources to identify repairable items for customer approval. Once agreed upon, SDI will implement the program, which includes tagging and tracking repaired parts, root cause failure data, and tracking warranty items. The results: savings of up to 5% of total MRO spend by leveraging repairs vs buying new, plus root cause failure analysis of critical spares to identify improvement opportunities.

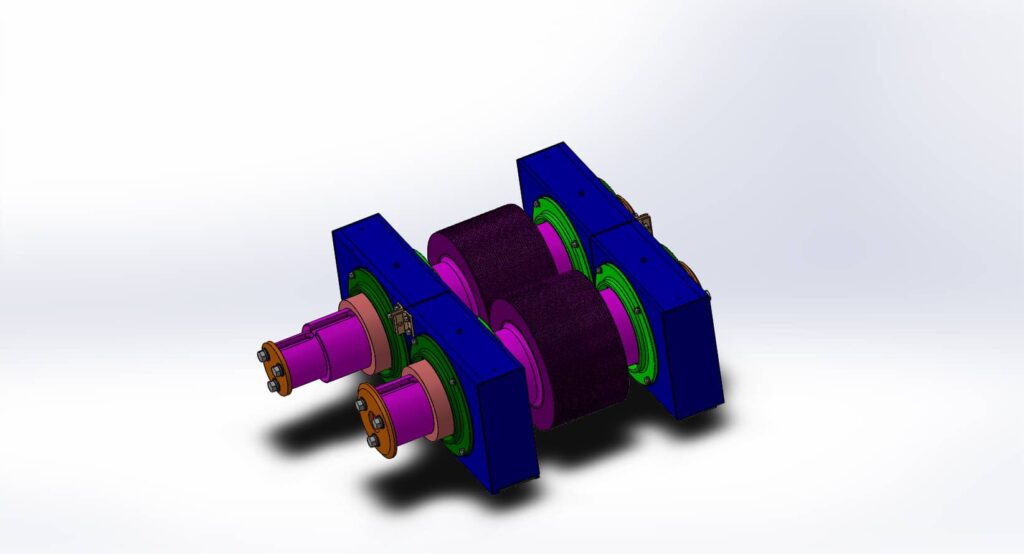

As industry changes, so do the products. Equipment becomes obsolete, and the cost of replacement equipment can be daunting. 3D scanning gives you the precision accuracy needed to produce parts with confidence – and savings. SDI can perform 3D scanning as a project service to reproduce difficult-to-measure parts and equipment. We use complex 3D scanning tools to capture, develop and compile usable drawings via CAD or SolidWorks. These contain the technical details interpretable by a machinist to create the needed component. You get a 2D drawing of the component, ready to be issued to a machine shop. If you don’t have a machine shop, SDI has a network ready, as well as re-engineering capabilities for the component if needed. The results: Savings in engineering time, downtime elimination, piece-price reductions, and avoiding capital expenditures.

SDI can perform reverse engineering as a project service, giving you control over the longevity of your equipment. Often in reverse engineering, SDI suggests methods to manufacture the part more robustly, cost-effectively, or with better fit – frequently all of the above. Sourcing standard MRO products identified as OEM parts saves up to 50%. Reverse engineering benefits include improved uptime, eliminating capital spending, cost reduction, shorter lead times, and extended asset life.

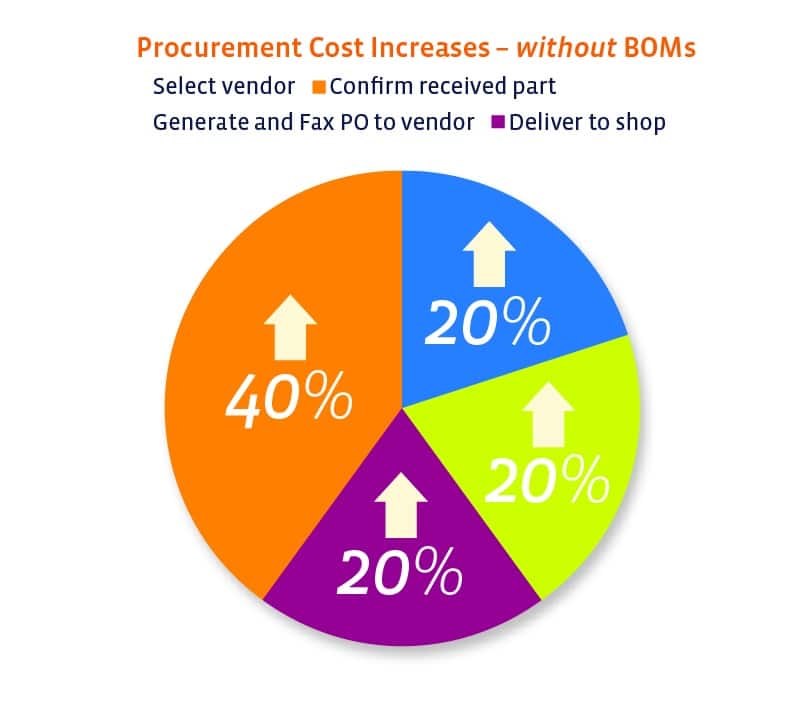

Recording accurate data on all equipment, parts, and linking parts to the correct equipment is fundamental for any reliability program. SDI can create material masters and bills of materials to provide accurate equipment data in the right locations. Our technical services engineers can assist your team in developing enriched material data beyond basic descriptions. While accurate data is vital for maintenance and reliability, capturing and maintaining it requires significant resources. Let SDI fill that gap. We can help with material creation, information updates, and bill of materials – all to drive your operation’s effectiveness.

Copyright ©2025 SDI, Inc.