It was just another day on the production floor when an unplanned part failure occurs turning it into a day of part searching to bring the line back up. Unfortunately, the expensive OEM parts for the shutdown equipment are only available overseas, and the one and only part stocked was just used during another failure four weeks ago.

Making things even worse the part has an eight week lead time. The replacement part will not be in for another four weeks. Production can be diverted to a slower line for only three days until it is scheduled for another order to run. This gives the Maintenance team 72 hours to get the machine up and running again.

This example can happen to any one of SDI’s clients at any facility. With the use of new technology and SDI’s onsite Reliability Engineers, these problems can be dramatically reduced or completely eliminated.

How and what are the new technological tools that will help the customer with the failure scenario described above? These tools will allow SDI to accurately laser scan parts, analyze the “weak areas” of the damaged parts, redesign the part to eliminate these weaknesses, produce a 3D printed prototype, reduce the part cost, eliminate the overseas lead time, and produce a working replacement part within 72 hours. All of this while simultaneously reducing our client’s maintenance and inventory costs with a marked improvement in the actual life of the part between failures.

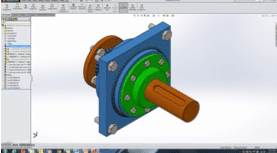

With tools like multi-laser hand held scanning devices, SolidWorks computer modeling software, 3D printing technologies and SDiTRACK software, SDI will be able to help our customers with the problems in the example through its Re-Engineering program.

Let’s step through the failure presented and explain how SDI’s new technology can solve this customer’s part failure.

Scenario #1:

It was just another day on the production floor when an unplanned part failure occurs turning it into a day of part searching to bring the line back up. Unfortunately, the expensive OEM parts for the shutdown equipment are only available overseas, and the one and only part stocked was just used during another failure four weeks ago.

With the use of hand held 3D scanners, Reliability Engineers will be able to scan the broken part as well as the mating parts against which it mounts. By 3D scanning the mating and broken parts, exact fit up is guaranteed. Using 3D scanning technology, SDI will be able to duplicate a specialized part with extreme accuracy and speed. Since a good part was not available to measure, the 3D scanning equipment allows SDI to re-engineer the part instead of rushing the very expensive OEM part from overseas. Also, this technology will provide the foundation for even further re-engineering solutions.

Scenario #2:

Making things even worse the part has an eight week lead time. The replacement part will not be in for another four weeks.

Once the parts are 3D laser scanned, SolidWorks 3D models are generated from the 3D scanning conversion software. SolidWorks modelling technology is then utilized to analyze where the part is the weakest with the failure mode force loads applied to it. This modelling process is called ‘Finite Element Analysis’ or FEA. Once the weakest areas are exposed, they can then be ‘designed out’ with better features such as improved materials or modified geometries. The software allows the design improvements to be verified through a “failure mode simulation” to quantify the proposed redesign improved results.

This allows the re-engineered part to be machined locally at a reduced cost. Just having a SolidWorks 3D model of the part gives the machine shops the tool paths they need for their CNC machining centers. This means decreased set up time for the shop, thus reducing lead time while producing a part with longer life through design improvements. All of this power comes from the hand held 3D scanning and SolidWorks modeling technology SDI is now acquiring.

Scenario #3:

Production can be diverted to a slower line for only three days until it is scheduled for another order to run. This gives the Maintenance team 72 hours to get the machine up and running again.

72 hours is a short period of time to measure, engineer, and machine a replacement part… without the use of modern technology. With the 3D scanning and modeling tools available, it will give the client a fighting chance to have a part within 72 hours. Again, since accurate part models were quickly generated (typically a couple of hours from scan to solid model) this also allows a 3D printed plastic prototype to be produced within hours to test the parts for fit up. Once fit up is approved, a local machine shop can produce the part in an emergency case.

Once the part has gone through the re-engineering process, SDiTRACK software can be utilized to track the increased life of the parts moving forward. SDiTRACK can also be utilized to track failing parts to determine how often they fail and then target those ‘bad acting’ parts for future improvement through the re-engineering process.

This solution scenario is just one the many possible ways that SDI will lead the industry in reducing Maintenance costs for its clients. These technologies will give the Engineering Services team the tools to exceed client expectations!

Contact Us today to learn more about the power of 3D printing technology!