As industry becomes more sophisticated and competitive, the future of indirect supply chain management will center on eliminating uncertainty, increasing productivity, and transforming complexity into information-driven strategic decisions.

Globalization

Manufacturing firms can garner significant MRO sourcing, cost, and delivery advantages by engaging a supply chain service provider adept at negotiating the interdependencies of suppliers, service providers and customers the global marketplace create.

The best supply-chain-as-a-service providers leverage their:

- economies of scale

- optimized global networks

- management expertise

- standardized business processes

to generate lower cost bases and service delivery frameworks for clients. They cultivate backup manufacturing and distribution sources for a broad range of products to guard against the risk of disruption due to political unrest, natural disaster, etc.

Disruptive Technology

Unprecedented innovation and technological advancement are creating a new indirect supply chain paradigm. The near-universal availability of cloud-based computing, rapid development of purpose-built apps, and industry’s increasing capacity to collect, share, and analyze information sets the stage for effective MRO supply chain management to generate business success. Simulations and statistically significant data can be used to:

- predict component failure

- schedule preventative maintenance

- anticipate demand anomalies

- make other contributions to manufacturing productivity and scheduling

Attempting to develop procedures and responses to exponential changes in supply chain best practices is courting disaster.

Forward-thinking companies will partner with service providers that are positioned to identify manufacturing trends, anticipate obstacles to their clients’ success, and devise creative solutions that adapt and grow with them.

Advanced Cost Metrics

Basing supplier choice solely on price-per-piece not only ignores critical MRO materials’ cost components, but it also can lead to decisions that are contrary to a company’s strategic goals and detrimental to its bottom line. When cost-per-item is the only determinant, there is an incentive to order more product than needed in order to obtain volume discounts or to buy off-contract parts.

A supplier-agnostic supply chain partner can ensure the firm adheres to its selection criteria while considering all the contributors to total cost of indirect supply ownership. These factors include carrying costs, transportation charges, import fees, delivery reliability, etc. as well as the cost of company policies that may not be strictly optimal from a pure cost viewpoint. The policy of purchasing a certain percentage from minority-owned suppliers or not buying from vendors poor gender-equality, safety, or environmental records, for example. The partner will right-size inventory, saving money for expansion, investment, and other revenue-positive ventures.

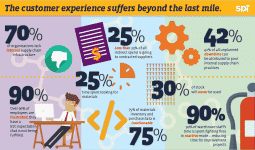

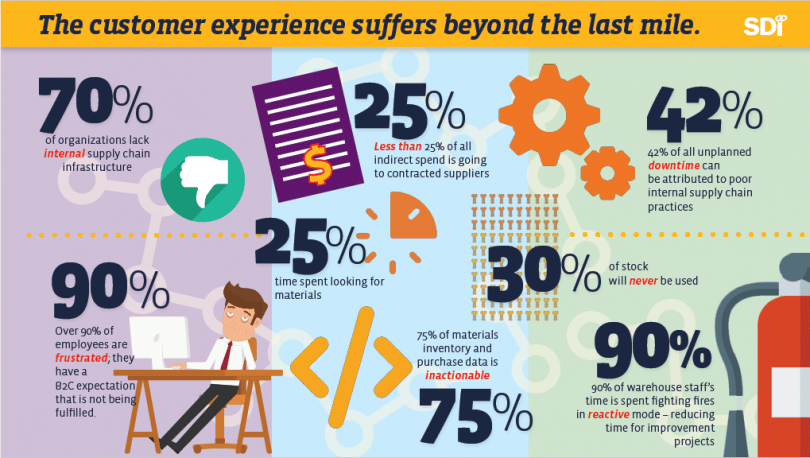

Beyond the Last Mile

The ultimate goal of indirect supply chain management is to implement the right supply at the right time. Unfortunately, in a world where components ship from the other side of the world in a few days and across the country in a few hours, getting them from the shipping dock to the production line often takes much too long. Orders of cleaning supplies that companies track every step of the way with sophisticated applications suddenly get lost in the shuffle, misplaced or misdirected on their way from the warehouse to the maintenance closet.

Companies today demand the same visibility, efficiency, and service that consumers take for granted when ordering online. Your supply chain management partner should offer mechanisms for getting your MRO supplies to not only to your place of business, but to their final destination – the employees that install and use them. In the final mile and beyond, the traditional business-to-business delivery model shifts to a business-to-consumer distributorship, requiring a different skill set.

SDI: Your Partner in a Changing MRO Landscape

SDI extends the indirect supply chain solutions it customizes for organizations beyond the last mile, from door to floor, integrating the critical products, parts and services seamlessly and efficiently into operations, facilities, breakrooms and storerooms. More than simple on-site fulfillment service delivery, our solutions include:

- strategic resource planning

- escalation support

- performance management

We develop processes that connect the inside to the outside, arming organizations with visibility into unmanaged purchases, transaction cost control, and purchase-to-use streamlining.

Contact SDI today to learn more about how we are responding to the dynamic indirect supply chain ecosystem. Ask how our products and services can help your company reduce piece price, purchase volumes, and SKUs, while optimizing planned maintenance scheduling and maximizing machine uptime.