The ideal plant maintenance room floor plan will make the most efficient use of available space—both square footage and vertical bins and shelving. It will include areas for receiving, storing, and staging inventory. Most importantly, it will allow warehouse and maintenance personnel to evaluate and classify inventory so it can be placed in its proper location based on criticality, frequency of need, accessibility, and other factors to ensure maximum manufacturing line uptime and productivity.

The floor plan should accommodate the maintenance team’s tasks by carving out areas where they can repair components and assemble parts kits and consumables as part of their scheduled activities. This includes storing heavy and bulky items close to the floor and in aisles wide enough for hand trucks and forklifts to maneuver. Smaller items should be stored in bulk, grouped by their applications. This will help workers identify redundant inventory and commodities ordered under different item numbers where you can consolidate vendors and reduce the number of SKUs you need to track.

The Elements of an Efficient Maintenance Room Floor Plan

An efficient floor plan will orient racks, bins, and shelves to minimize the time required to stock and pick from them. If you have not upgraded your maintenance room recently, a small investment in new equipment and labor will pay significant productivity dividends over the long term. Here are some issues to consider when overhauling or tweaking your maintenance room layout:

- Plan for Expansion – You expect your business to expand, so you should plan for your maintenance needs to scale along with your growth. Adding more manufacturing capacity will require equipment staging and additional spare parts storage. Open areas and empty shelves can accommodate temporary increases in SKUs as part of your company’s growth.

- Do Not Treat Consignments as Inventory – While consignment parts may be shelved in the storeroom, they should not be treated as paid-for inventory. Doing so creates financial gaps in the inventory report, generating imprecise and often negative views of storeroom management and preparedness because KPIs do not show an accurate picture.

- Assign a Gatekeeper – Unsecured storerooms invite misplaced and misappropriated inventory. Secure the storeroom and ensure it is monitored. Without these precautions, maintenance employees may “forget” to sign items out or may keep a personal supply of high-demand items. These ghost inventories and unaccounted-for uses lead to critical shortages and accounting miscalculations.

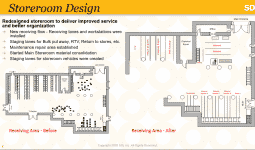

- Align Layout with Workflow – Your maintenance room should be configured to allow each task to be completed quickly and integrate seamlessly with downstream functions. For instance, receiving should have sufficient lanes and workstations for accurate verification and documentation while accommodating the retrieval of material from the dock for placement in its proper warehousing location.

Special Consideration for PPE Inventory Management within the Maintenance Room Floor Plan

Especially in the current environment, PPE inventory management deserves special consideration when it comes to proper storage and allocation. Gloves, facemasks and shields, and other high-rotation, high-frequency-of-use safety equipment must be easily accessible. That means they must either occupy space where workers can grab them within a minute or two, or else be located throughout the plant where they are needed. For the latter solution, consider vending machines that suppliers can monitor and restock as part of a vendor-managed inventory agreement.

Benefits of Optimized Maintenance Room Floor plans

You should begin to optimize your maintenance, repair, and operations storeroom as soon as possible. Every day of delay costs you money in the form of wasted inventory and lost productivity. The sooner you redesign your maintenance room layout and workflow, the sooner you can begin reaping the rewards:

- Greater maintenance efficiency and fewer major repairs

- Reduced waste from slow-moving and obsolete inventory

- Less risk of bodily injury and equipment damage

- Fewer stockouts and costly expedited shipments

When you’re ready to redesign your maintenance room floor plan, give SDI a call to ensure your facility is as efficient as possible. We have developed a Six Sigma approach to storeroom layout that maximizes accessibility and arranges SKUs in logical, intuitive arrays. Our services include customized workflow analysis, space evaluation, management policies, automation, and other best practices that combine SDI’s industry expertise and our best-in-class data science. Contact us now to put all these resources to work for you.