Manufacturing companies are increasingly beginning to understand that indirect materials—maintenance repair and operations (MRO) materials in particular—are well deserving of serious attention. For the typical manufacturer, MRO takes a back seat to direct materials procurement.

These indirect material orders are typically placed in high volume quantities and are usually relatively low value products making this area an often overlooked area for cost savings.

With hundreds, sometimes thousands of suppliers to choose from it is easy for buyers to choose a supplier that is not best suited for the specific situation. Because MRO purchasing is not seen as a strategic method to save the company money and improve inventory management, many storerooms become under-managed and inadequately stocked.

Although MRO does remain a backwater in many organizations, it is clear that substantial financial and operational benefits are “just beneath the surface.”

Why Should I Care About MRO Purchasing?

MRO purchasing is typically not a top-of-mind issue for most manufacturers. It’s not seen as a critical operating component and does not receive the attention—staffing and management attention—that is given to the procurement of direct materials.

Studies have shown that, while the actual cost of MRO purchases may only be around 15%, or so, of the cost of goods sold, the number of purchase transactions can be 60% or more of total requisitions. This means that an inordinate amount of administrative time is spent on purchasing and managing these items. This is compounded by the following common situations:

Wide Variety of Buying Personnel:

- The buying staff handling MRO requisitions and placing the orders are typically administrative employees, who are not experts in modern sourcing and procurement disciplines.

- They are not specialists, like the buyers that you often find purchasing direct materials. This means that they must rely on skilled manufacturing engineers and maintenance staff for support, diverting them from their primary responsibilities. “The assembly line’s down, we need that part now! What happened to that requisition?”

Inefficient Multi-Location MRO Purchasing:

- In multi-location organizations, MRO buying is typically localized and assigned to administrative staff. While this may be efficient for large locations, small locations will frequently lack adequate knowledge and expertise.

- Without a unified MRO purchasing approach, there is significant potential for over-buying and little opportunity to attain economies of scale—both in terms of the numbers of buyers needed and the aggregation of items purchased.

- Because the “buying resources” are splintered across locations, there is little flexibility to deal with the ebb and flows of requisitions.

Lack of MRO Spend Analysis and Supplier Rationalization:

- Without an overall procurement approach, little emphasis is being placed on assessing what’s being purchased and from which supplier—frequently resulting in over-buying at inflated prices.

- With overstretched and inexperienced purchasing staff, there is little opportunity to aggregate MRO purchases and to negotiate improved pricing and service arrangements.

Likewise, with hundreds of suppliers and overlapping product lines, it is difficult to identify the best suppliers and establish preferred relationships with them.

Ineffective MRO Purchasing Systems:

- In most manufacturing firms, purchasing for direct materials will be handled by centralized procurement professionals, whereas MRO purchasing will still be managed locally.

- The mechanisms for managing and tracking those purchases are sometimes rudimentary at best, especially given their perceived level of importance and lack of management attention.

- Even when systems are in place for MRO, it is unlikely that they are integrated with the supply chain, using established ecommerce techniques, such as electronic data interchange (EDI), for order placement, order status, shipment reports, etc.

- At best, the systems will require significant manual intervention and be prone to error, in terms of:

o Ordering the correct pieces, based on clean data

o Confirming order placement with the supplier

o Monitoring order fulfillment and shipment

o Receiving and issuing items to and from local store room inventory, and

o Validating correct receipt and handling appropriate supplier payments.

Inadequate Control of MRO Store Room Inventories:

- Once the materials are received, they are most likely placed in store rooms under local supervision, usually without the controls in place that are as rigorous as those for direct materials.

- Without a unified approach to managing MRO stores, there is potential for an expensive build-up of inventory, combined with obsolescence.

- You’ll also find “private stashes”—where individuals keep their own stock of items to make sure they have what they need, when they need them.

Clearly, this overall situation is not the most effective way to operate production facilities. Even though the value of MRO purchases may be a fraction of direct materials procurement, there are still significant operational and purchasing efficiencies to be found.

What’s needed for MRO Purchasing?

Nobody says that the MRO supply chain is simple! Professionals have spent entire careers in the field—and are still learning new wrinkles.

Don’t Do It Alone

While a do-it-yourself approach is possible, unless you have the trained in-house experts and are willing to invest in technology it’s much more viable to work with a third-party MRO supply chain provider, in terms of:

- Efficiencies and economies of scale

- Depth and variety of expertise

- Systems sophistication and maturity

- Breadth of supplier and vendor knowledge and relationships.

Leverage the services of a specialized MRO service provider. With their help, it is possible to institute a unified, top-down approach to MRO purchasing and streamline your end-to-end MRO ordering process. This will enable you not only to reduce purchasing and inventory costs, but also to improve the effectiveness of your plant operations.

Your MRO purchasing process can be streamlined, by implementing:

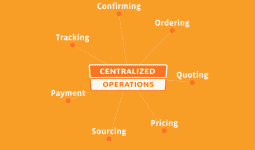

Centralized procurement services—a single center for buying and confirmation, utilizing the service provider’s procurement team. This will reduce your contacts from hundreds of suppliers down to a single point—handling all purchasing transactions processing and payments for all suppliers.

- The service provider’s buyers should have the expertise and resources to research parts thoroughly and leverage reliability engineers and site managers before issuing a PO.

- Strategic sourcing can ensure that items are purchased from the best suppliers for the best value.

- Buyers should also be able to evaluate order history, considering your needs when searching for requested parts with better prices and more reliable delivery.

- Because of the provider’s economies of scale, they are able to handle the ebbs and flows of your purchasing workload—even during seasonal peaks.

MRO supply chain integration—connecting your purchasing system with the service provider’s to access their eProcurement capabilities and linkages to your supplier network.

- Your service provider should have robust eProcurement systems and ongoing connections to vendors in your supply chain.

- These systems should allow suppliers of all sizes to self-confirm systematically and provide complete visibility into order statuses—from requisition to delivery. The suppliers can confirm that POs are received and then electronically transmit back the expected product delivery date.

- Using electronic data interchange (EDI) you’re assured that all POs and acknowledgements are communicated automatically, without the expense and risk of error inherent in manual entry.

- You should no longer need to chase purchase orders—all your MRO purchases should be updated in a single repository for your review.

- In addition to EDI, service providers may offer support of cutting edge technologies such as intelligent Optical Character Recognition (OCR), and radio-frequency identification (RFID), to name a few.

Strategic Sourcing Practices—leveraging your service provider’s experience to introduce elements of strategic sourcing that are currently out of your domain of expertise. They’ll be able to introduce practices and techniques such as:

- Spend analysis and category management to reduce the number of suppliers and facilitate preferred vendor and pricing relationships

- Just-in-time programs to improve operational performance and optimize cash flows

- Automated and adaptive procurement for stock items, consumables and break/fix items that are generally inventoried for regular usage.

Getting Started

MRO supply chain offerings are mature, repeatable services and providers have well-honed implementation processes.

Generally the process will begin with an on-site MRO supply chain evaluation and assessment of your current MRO processes. This will include:

- Interviews with key stakeholders and end users, using ‘voice of the customer’ techniques that encourage dialogue and candor

- A walk-through of how materials are currently requisitioned and issued, as well as reviewing your sourcing, purchasing and back office support processes

- Benchmarking your storeroom performance with a formal evaluation tool.

Custom Fitted Approach to MRO Management

Following the assessment, your provider will be in a position to present your total MRO costs, as well as areas for improved efficiency productivity and cost reduction.

They should also be able to present a customized MRO supply chain strategy, including a complete scope of work, implementation and change management plan, plus a detailed return on investment.

The bottom line is that, at this stage, you should have all the information you need to commit to a new MRO procurement approach, streamlined with an end-to-end or As-a-Service MRO solution tailored to your company needs.

Need Help?

Do you need advice on streamlining your MRO supply chain? Whether you need help every step of the way, or only with some aspects, SDI is here to help. Contact us to find out how we can help your business!