Whether your maintenance crew needs to make unscheduled emergency repairs or conduct routine preventative tasks to keep your facility running at optimum efficiency, a well-organized and well-maintained storeroom is critical. The maintenance, repair, and operations (MRO) team can function only when the right parts are in stock, tools are in good working order, and repair manuals are up to date. But having these resources somewhere in the storeroom is not enough. Not only must they be available, they must be accessible quickly in order to keep equipment downtime as short as possible. That’s where the maintenance storeroom layout comes into play.

Organizing a storeroom takes a lot of time, planning, and effort. Unfortunately, MRO managers often are too busy locating misplaced tools, reordering supplies that are soon to run out, replacing parts damaged in handling, making room for imminent deliveries, and fighting other imminent brushfires. The irony, of course, is that if the time is taken to create a neat, clean, and standardized storeroom, many of those inefficiencies and time wasters go away.

Setting up a maintenance storeroom layout correctly and establishing rules for its operation and management may be resource intensive, but the results are truly worth the effort. SDI has helped hundreds of manufacturing companies and process plants design and build a maintenance storeroom layout that improves production efficiency and cuts inventory costs. Here’s what we have learned from our decades of experience:

The Maintenance Storeroom Layout: A Blueprint for Success

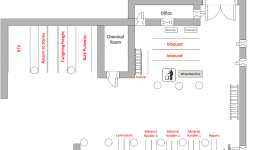

A considered maintenance storeroom layout will make the most efficient use of the available space while minimizing the time and labor required to document, store, locate, and retrieve the parts. Handling a part more times than necessary between its arrival at the receiving dock and its ultimate installation on the floor wastes workers’ time and increases the chance that the component will be damaged or misplaced. When designing the storeroom and choosing shelving and other storage containers, consider these factors:

- Frequency of Use – Group parts based on how often they will be needed. The parts that will need to be retrieved most should occupy the most accessible space.

- Criticality – Parts that are central to production also should move to the front of the accessibility line. When critical parts fail, you want your crew to be able to obtain the replacement and get to work installing it as quickly as possible.

- Size – Large, cumbersome components must be stored in areas with plenty of space so forklifts and material handlers can manipulate them without banging them against walls, shelves, or other parts. Be sure the shelving you pick for large parts is wide and deep enough to accommodate them.

- Correlation – Spare parts that belong to the same equipment or serve similar functions should be stored together. Put motors in one spot and pumps in another. Or put all the condensers, heat exchangers, valves, and mixers that are used with a specific homogenizer in the same location.

- Nomenclature – Be sure to clearly label all parts, aisles, shelves, and drawers using a consistent and intuitive taxonomy. Keep accurate records of each part’s location: Aisle 1A, shelf 6, tier B, for example. If the cabinets in one aisle are numbered left-to-right, top-to-bottom, every other aisle should be coded likewise.

Workflow: A Well-Oiled Machine

Much like the production process itself, maintenance and repair functions require logistical precision to ensure workers can account for every part that enters, moves around, and leaves the facility. Proper layout also facilitates warehouse workflow. When parts management follows a logical pattern, workers can shave time off their parts management activities.

Well-spaced corridors give storeroom workers direct access to the pieces they need without forcing them to wend their way through a maze of shelves. Codifying work rules, automating processes, and ingraining the importance of order in every stockroom employee will reduce errors and waste. Storerooms should be designed and laid out to ensure parts handling can follow a logical, one-way, flow chart as they progress through the system:

- Receiving – Clerks ensure the order form, packing list, and actual parts shipments match. Check quantities, prices, and condition.

- Stocking – The physical transportation and placement of received parts from the delivery staging area to their proper location – on pallets or shelves or in bins, cabinets, or drawers.

- Picking – The process for knowing where to find each part at a moment’s notice. This includes catalog access, physical access (forklifts, ladders, hand trucks, etc.) and recording of part movements.

- Inventory – Keeping accurate count of quantities, demand forecasts, order triggers and a process for auditing these figures and resolving discrepancies.

- SLOB Management – Identification of slow-moving and obsolete (SLOB) inventory. Infrequently used parts are candidates for downwardly revised inventory levels, reducing carrying costs and freeing up storeroom storage space.

Create a Maintenance Storeroom Layout That Delivers Results

SDI has developed a range of storeroom optimization services. We can tailor software and harness our expertise to build policies and management best practices that increase MRO storeroom productivity. Just as important, we have the technology and expertise to streamline storeroom processes and make them more efficient. Call on us for a complete diagnostic of your MRO routine and storeroom layout.

Our experts will design an approach that leverages your personnel’s strengths, warehouse geometry, and management input. We take the time to understand the challenges facing your front-line MRO staff and supervisors. The result is an insight into storeroom control and execution.

Just as important, we will help you manage the change to a strategic approach to MRO workflow. You will notice improved fulfillment and service times, lower handling costs, less waste, and a better use of data. Contact us today, and we will mobilize our team of on-site professionals to implement procedural guidelines, facility design, and process automation.