Home » Supply Chain Services » Source to Pay

SDI’s source to pay service starts with our strategic sourcing strategies.

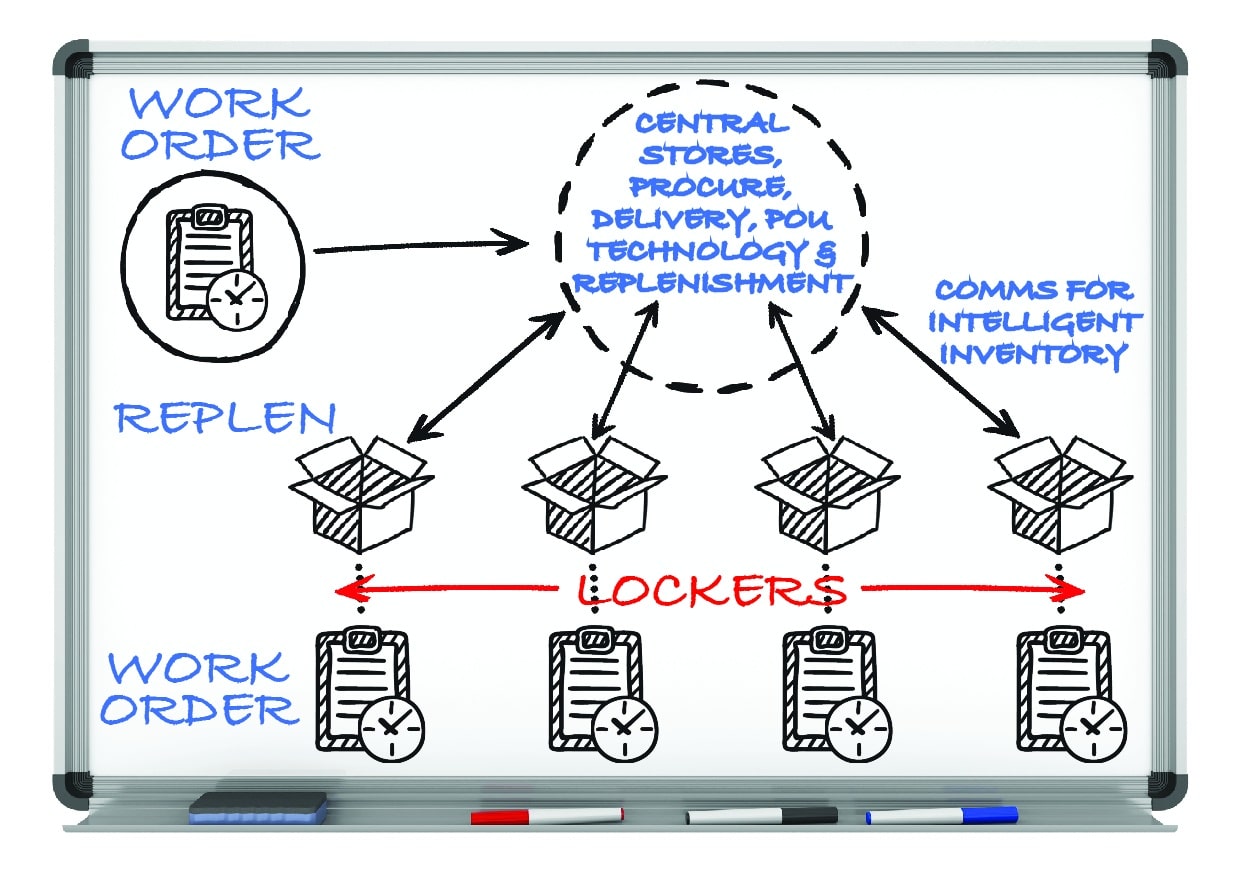

For manufacturing and other multi-site facilities, we first set up a strategy for your stock items, consumables and break/fix items that are generally inventoried for regular usage. The MRO procurement process for these items is automated and continually runs against our adaptive demand planning algorithms, to constantly optimize inventory levels.

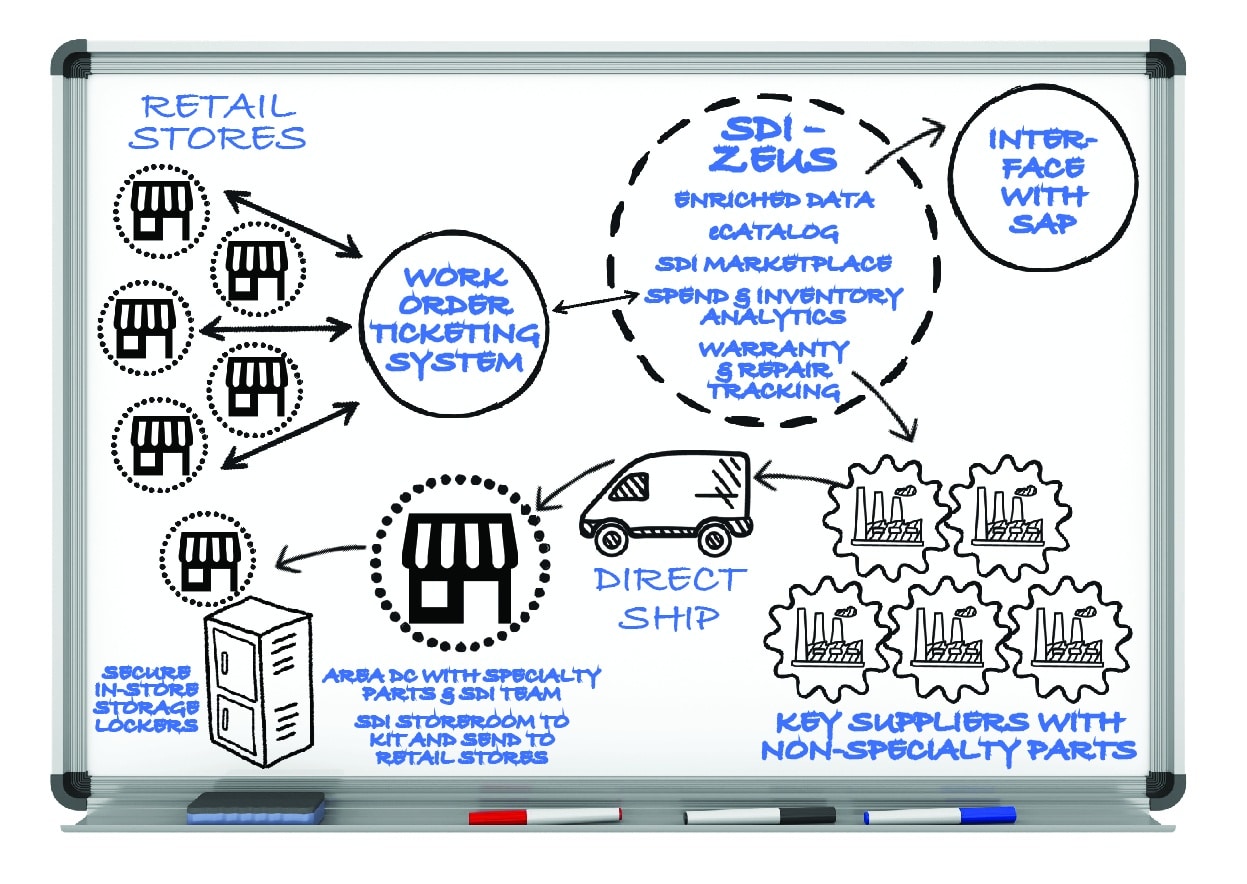

Our hybrid S2P model lets us leverage our entire portfolio for more streamlined, efficient and scalable MRO and tail-spend procurement processes. Our procurement group focuses on compliance to pre-determined sourcing strategies, while our buyers’ deep category and industry knowledge helps ensure accuracy and the most efficient outcomes. The center-led S2P indirect procurement model allows our buyers to focus on your overall maintenance supply chain needs, while on-premise resources provide high-level customer touch points.

Utilizing the proven tools provided by our strategic sourcing division, our buyers can ensure compliance that the right parts are always purchased on the right contracts. We offer a multifaceted approach that includes a combination of tactical buying desks, eProcurement technology, and experienced professionals with deep breadth of FM & MRO category expertise from frequency in the market.

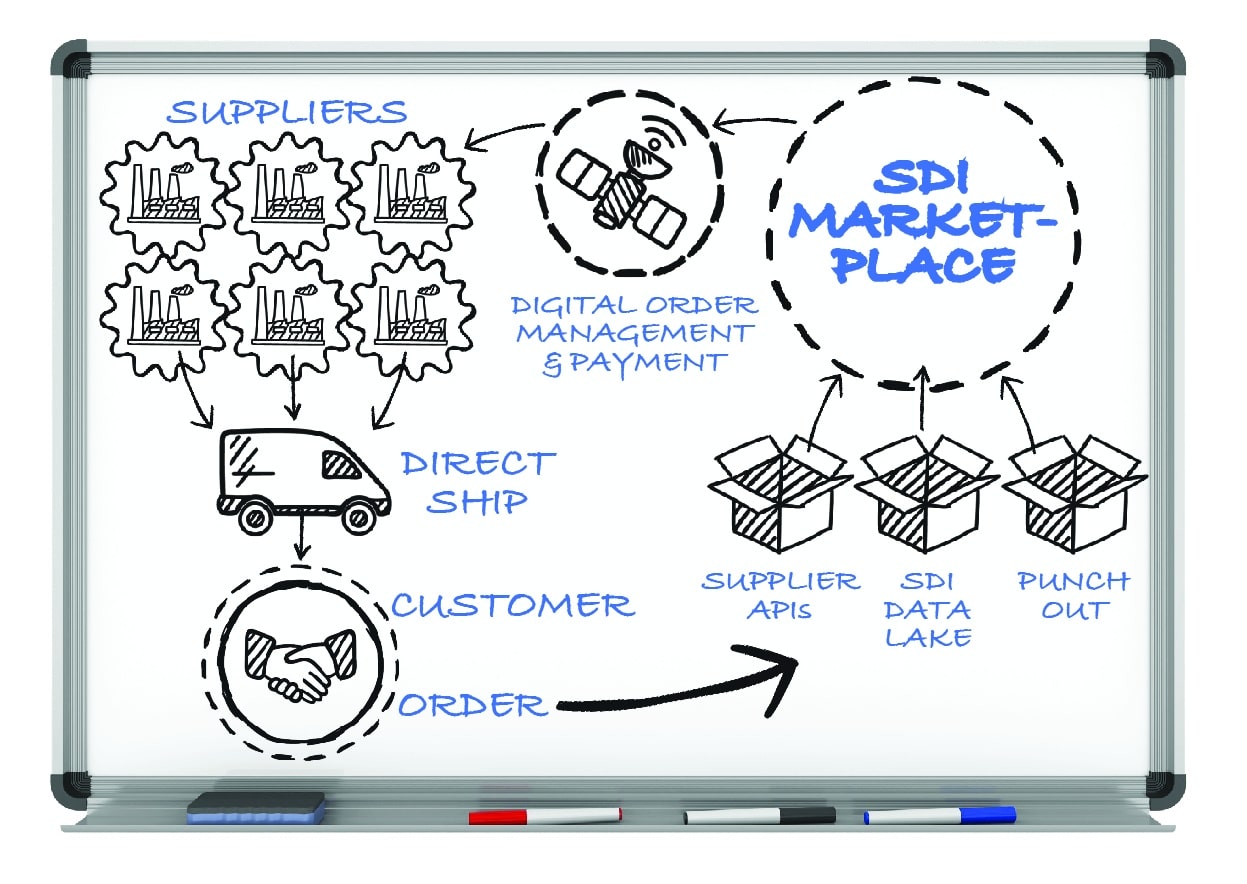

Once we’ve strategized for your catalog items, consumables, and critical spares, SDI harnesses the power of cutting-edge technologies and proven methodologies to manage and interpret electronic data effectively. This streamlined approach ensures efficient transaction processing with your supply base, leading to cost savings for our clients. Our system communicates orders, acknowledgments, and deliveries to the supply network, providing real-time visibility into purchase orders. This eliminates the need to chase down purchase orders and offers maintenance technicians real-time alerts and status updates for improved efficiency.

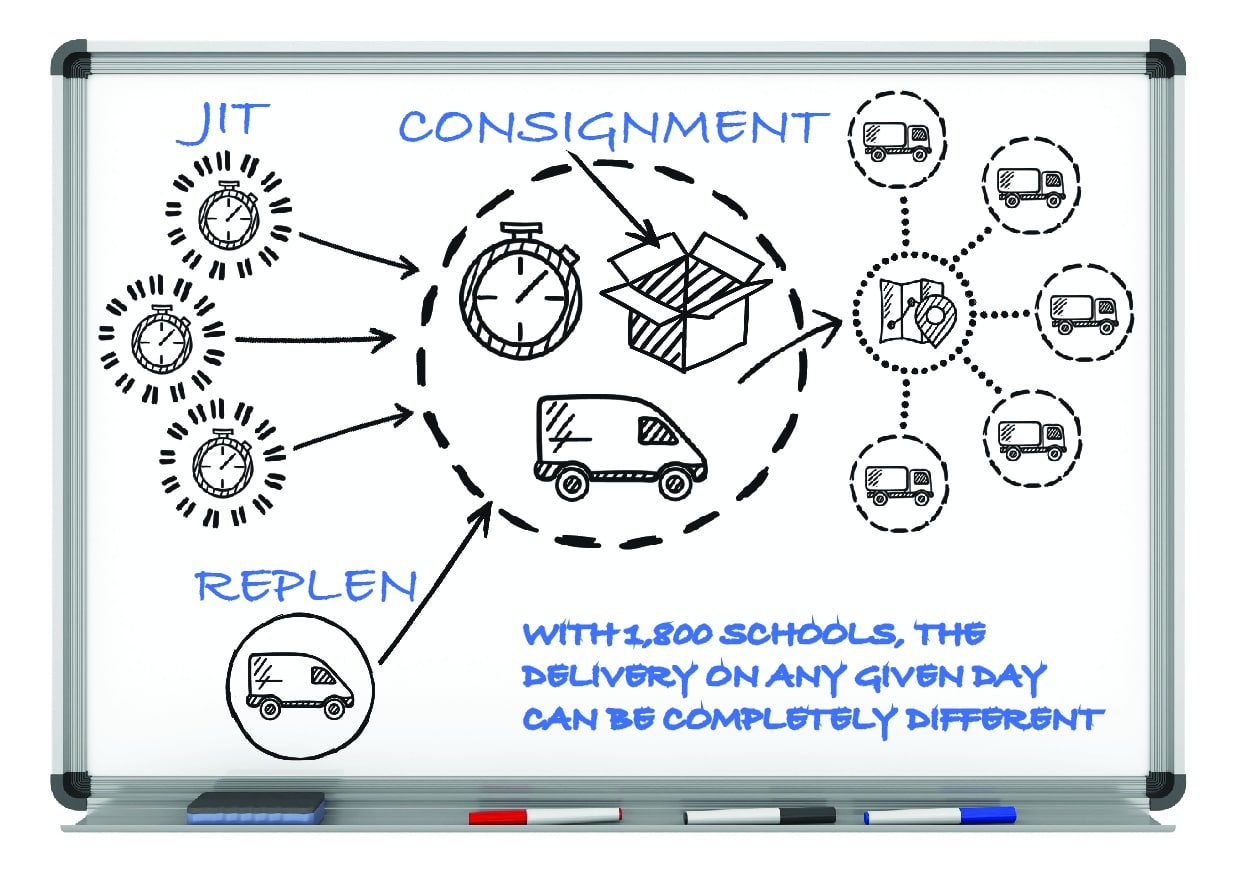

Collaborating closely with your teams, we tailor a fulfillment model to meet your distribution needs, including variable-destination work order fulfillment, fixed-destination milk runs, and procure-to-drop ship models. Our omnichannel fulfillment solutions offer integrated supplier ordering assistance, local will-call pick-up, and electronic pick-pack, routing, and delivery systems. These solutions provide real-time visibility into order and delivery status, enhancing enterprise-wide efficiency and control.

Whether on-site or off, SDI storeroom management staff focuses on transactional inventory management (issuing, receiving, cycle counting and reconciliation), customer service and continuous improvement. The ZEUS Digital Supply Chain Management system connects seamlessly with your current inventory and work-order management set-up.

In a traditional ordering process, technicians often struggle to locate needed parts, resulting in lost repair time spent online, on the phone, or traveling between locations. SDI’s Integrated Parts Management programs revolutionize this by equipping field technicians with a single mobile app for ordering common items, even non-catalog items. They can also upload photos of parts and equipment, all while at the job site. The program also provides order tracking in the mobile app, allowing technicians to plan their work schedules more efficiently.

SDI utilizes electronic data transmissions with its supply base to streamline transactional processing—passing the savings on to our clients. By communicating orders, acknowledgements and deliveries from SDI’s suppliers, our system ensures all purchase orders are delivered automatically and all FM and MRO purchases are updated in a single repository to be easily viewed by our clients – no need to chase POs. We confirm electronically, so client sites always know when to expect delivery.

From a billing perspective, SDI invoices its service fee and the pass-through cost of product purchased in a summary statement twice per month. This eliminates the hundreds, if not thousands, of vendor payments currently made each month – a tremendous reduction in processing costs.

Our Integrated Parts Management solution offers a dedicated Technical Parts Support Team composed of part-sourcing experts with technical backgrounds and trade experience. This team communicates effectively with field technicians, using their experience to help solve challenges in locating parts. The Parts Team acts as a translator, explaining technical details to non-technical groups and providing access to a wealth of technical information directly from the mobile app.

Access to equipment manuals, bill of materials, quick reference guides, and more within the app saves technicians valuable time, eliminating the need to return to their trucks or shops to locate manuals.

Our data-driven, digital supply chain approach enhances transparency, improves responsiveness to demand, and identifies savings opportunities. We specialize in getting more spend under contract through category expertise and driving compliance to negotiated contracts, ultimately achieving the savings and performance improvements that matter most to your organization. Our tailored solutions ensure your FM and MRO procurement processes are efficient, cost-effective, and fully optimized.

Copyright ©2025 SDI, Inc.