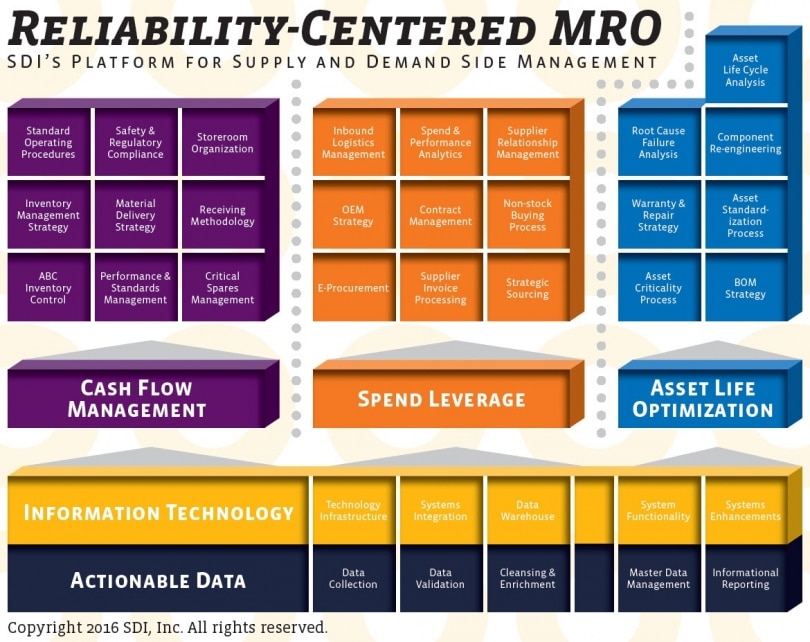

For the last 50 years, we’ve built our solutions to address the needs and pain points of our customers. We call our platform for supply and demand side management, Reliability-Centered MRO because it focuses on ways to make our clients’ production lines and facilities more reliable. And whether you’re in procurement, operations or maintenance, the common goal is ultimately reliability.

It starts with actionable data and information technology – the infrastructure and the data from which any endeavor to manage MRO stems. From there, we can execute on one or all of three different strategies:

- Cash Flow Management, which focuses on the storeroom as a way to manage the MRO supply chain

- Spend Leverage, which focuses on procurement

- Asset Life Optimization, which lives in both the storeroom and procurement but typically involves a reliability engineering and maintenance component as well.

One component of any Asset Life Optimization strategy should also be a Warranty & Repair Strategy. Research shows that typically 10-15% of items are repairable, representing about a 5% savings against total new item spend. As part of our Asset Life Optimization strategy, SDI has a process for tracking repairs and performing root-cause failure analysis that allows us to more easily identify common failures for our clients, and address them. Our goal is consistent reliability – to focus on causes of failure and reduce them. We also handle the warranty process and partner with repair vendors that can bring assets back to factory standards. This collaboration provides greater visibility into root-cause failure analysis, thereby improving reliability. It’s a more sustainable and reliable way to find greater savings in MRO.

Coming in January, we’ll reveal a brand refresh on our Warranty and Repair Tracking Program in addition to some exciting partnerships and other great news.

![]() Click here to view the image below in a larger format or to download

Click here to view the image below in a larger format or to download