Series Summary

Our “Game Changing Integration” three-part series explores the MRO technologies SDI utilized to improve Ascend Performance Materials business initiatives and incur $10 million dollars in savings. Part One, “Game Changing Integration Shortens the Distance Between Promise and Performance,” describes the current landscape of companies placing limited value on MRO technology and redirecting resourcing to “higher value” business initiatives. Utilizing a real-life example, part two, “Case Example of Skepticism, Pain, and Drive to Improve,” explores Ascend’s decision to overcome its skepticism and drive improvement with SDI’s customized solutions. In this final part of our three-part series, we take an in-depth look at how configuration-based integrations outpace code-based integrations with overwhelming benefits. The high-value improvements Ascend experienced with SDI’s partnership prove that the skepticism surrounding MRO is not only unsubstantiated but resulting in lost opportunities and savings for many organizations.

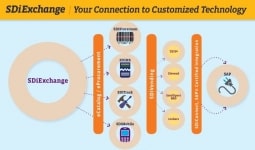

Moving from Code-Based to Configuration-Based Integrations

The old methods of SAP integration involved a lot of custom coding. We have changed the integration game by moving from custom code-based integrations to configuration-based integrations. Offering numerous organizational benefits, a configuration-based process:

- Delivers more logical interfaces saving customers time and money

- Exposes problems in the system by making the interface more straight forward and easy to understand

- Requires nothing to be installed in the client’s SAP landscape

- Accommodates project requirement changes easily, even during deployment, with a nimble structure

We find that every integration has two key parts – first comes the blue print and then the team implements based upon the blue print. As with all integrations, things evolve. It’s not that things don’t work to the original blueprint, but during the integration the team realizes that more data or different data is required to improve the integration processes. SDiConnect can easily take the system and its data out of production and then put it back into production…seamlessly. The process of the system moving in and out of production can be accomplished with no major changes to requirements. These activities would take months when deploying in a code-based landscape. In a configuration-based landscape, you can do in hours and days what would normally take months in a code-based environment.

SDI’s Nonintrusive Integration Process

We understand that each integration is unique – even within the same industry and across the same modules. What we do to drive efficiency, in unique environments, is to create a baseline template as a generic transactional set of data and rules. We then use and modify the baseline so it works for each unique deployment. We have an asset in terms of a reusable set of transactions that are easily manipulated to deploy across any company environment. This process of developing and modifying a baseline set of transactions enables us to deploy faster, better, and cheaper and without much IT involvement.

We install nothing in a client’s SAP landscape. We are not intrusive. The only thing we request of a client’s IT team is to set up a SAP user and only give us user privileges and access to the data for the interfaces that we deploy. This limits our impact on the client’s IT staff. They only have to set up a user and give us access and abide by privileges that are governed by SAP security.

Impact of SDI’s Efforts

As a result of these efforts, Ascend and SDI were able to:

- Exceed their performance goals

- Incur $10 million in savings per year

- Consolidate the IT organization to one system resulting in less processing errors

- Condense the time frame invoices are paid

- Improve master data ownership and processes for IT

Ascend incurred a huge backlog of processing errors when using EDI technology, which have been nearly eliminated with the new integrated system. Errors sometimes still occur, but it is easier for the team to identify and correct them in almost real time.

As Sheree Fields, Sr. IT Director of Enterprise Applications at Ascend stated, “our company is in the business of making nylon, plastics and polymers. Procurement made a decision that they didn’t want to be in the business of MRO. Based upon that decision they outsourced procurement to SDI. The combination of ZEUS (a technical solution) and the SDI team (a process solution) provides us with fully integrated MRO business support. The value to us – we can source maintenance and procurement activities to an outside provider while integrating and controlling our in-house maintenance activities – which is critical to the reliability of our business. This level of integration is the biggest complexity and greatest value.”