As a global manufacturer of the nylon, plastics, and synthetic fibers that are found in thousands of different commercial and industrial products, Ascend Performance Materials touches everything from carpeting to tires, apparel to agricultural products, and animal feed to personal care products.

Intent on always being a “reliable supplier” for its global customer base, Ascend completed an internal assessment of its indirect supply chain needs in 2009 and realized that it required a better way not only to manage its maintenance, repair, and operations (MRO) procurement and the costs associated with it, but also to align its MRO supply chain with its overall production reliability strategy. Not an easy task. Ascend’s manufacturing sites are vast and complex. Most plants are 1000+ acre petrochemical sites where consistency and control – especially in health, safety and environment – are critical.

Planning for Long Term and Sustainable MRO Procurement Improvements

Procurement led the strategic MRO initiative to reduce costs, optimize inventory, and improve reliability. The team had early success, but quickly realized that their ability to sustain process improvements, deliver on-going cost savings and leverage spend across the enterprise would be limited without integrating systems, improving data integrity, and reducing the number of manual interventions. To deliver on the original goal, Ascend had to fully integrate into SDI’s MRO Platform, ZEUS.

Sheree Fields, Sr. IT Director of Enterprise Applications, joined Ascend in 2011. By the time Sheree joined the organization the integration was well underway. Entering into the process, she defined herself as a skeptical leader of the initiative. She had many concerns including:

- Is Ascend comfortable allowing a vendor to manage its procurement?

- How will Ascend maintain control while shifting MRO process ownership and data management via the cloud?

- What impact will the integration have on the IT and maintenance organizations?

- What is the expected time to additional value from the new MRO platform?

- Is the MRO integration worth the time and attention of the IT organization?

While apprehensive in changing models, Sheree was also aware that the performance targets defined by procurement couldn’t be achieved unless Ascend fully integrated its SAP system with ZEUS. The IT organization had trouble with master data ownership and updates. The process of tracking and updating material costs in the system was cumbersome, redundant and time consuming. On the backend, Ascend had a huge invoice backlog where it had a really hard time reconciling invoices back to procurement…and paying its thousands of MRO vendors. The process of tying the 3-way match detail back to both the SAP and ZEUS systems perpetuated a lack of confidence in the data. Finally, the lack of visibility and real time data severely impacted the relationship between procurement, planning and maintenance.

Sheree understood that a lack of trust and credibility with the business would continue unless something was done to dramatically improve MRO processes, data integrity, and the relationship with procurement, planning and maintenance functions.

Emergence of a Game Changer to Move IT from Inspiration to Action

As Sheree stated, “Once procurement defined the strategy to move forward with SDI then it was up to our team to define how best to set up the IT landscape so that the MRO process is efficient and effective for IT and the business. When sitting in our position, anytime you hear integration with SAP you think custom coding, big budgets and long timeframes.” Sheree added, “There were so many process touchpoints between the systems that didn’t have pre-built APIs that we thought customization efforts were going to consume a great amount of time and resources.”

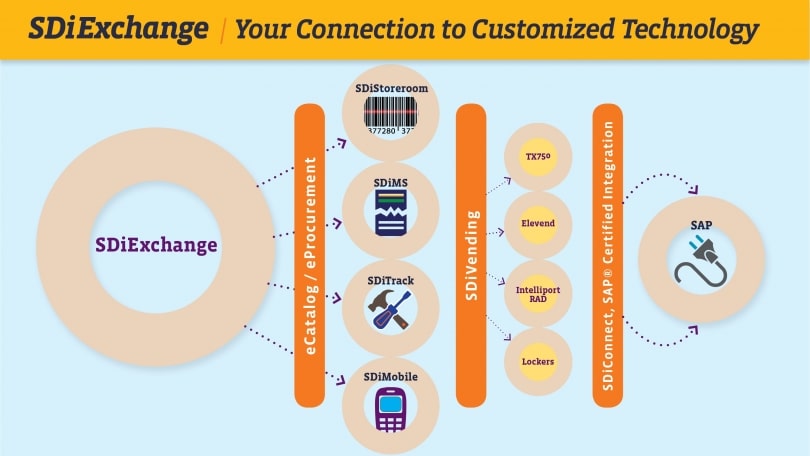

When SDI proposed their solution – SDiConnect – to integrate Ascend’s SAP system with ZEUS, there was a healthy amount of skepticism, but also optimism. If this solution actually worked, then the IT organization would shave off months or up to a year from the original projected implementation timeframe. The biggest selling point of SDiConnect was the flexibility and dynamic nature of the solution compared to traditional EDI technology. SDiConnect offered a fully integrated solution – meaning when the system of record makes a decision, either the master data changes or a purchase order is created, then within a few minutes that data is replicated across partner systems (back and forth). The comprehensive and almost real-time replication of transactional data is a huge differentiator. SDiConnect, resides between two more robust, but very rigid systems (SAP and ZEUS). In essence, SDiConnect, bridges the gap between the way two very different systems think – which makes the process streamlined and the data more reliable.

To manage expectations and risk, Ascend staged its rollout with the vision of delivering value to the business without too much disruption to the IT team. Being able to have this option from SDI at no additional cost helped Ascend save a tremendous amount of integration work. It made the implementation faster and easier…and much less expensive for the IT organization to support. The resistance that was present from Ascend’s IT team was essentially eliminated. The IT team was able to focus on what it would take to conduct the transactional activity more efficiently which gave the entire MRO team the time and confidence to focus on process improvements.

Sheree shared, “I would say that we were pleasantly surprised at how smooth the integration really was. We truly have become a believer in SDiConnect and the integration between SAP and ZEUS. This was a very positive experience which made us a believe that we could do this type of integration again in the future.”

Explore the final part of our series, “Inside the Game Changer: Configuration-Base Integrations, A Unique MRO Solution,” to learn how SDI utilized a configuration-based integration rather than a code-based integration to maximize Ascend’s processes. To learn more about the technology platform that enables SDI’s indirect supply chain management, click here.